a sand plaster basecoat.

I call these ceilings "boat ceilings' because they

look like an upside down boat. They are sort

of a rectangular dome. The arrises (inside corners) start out as a sharp corner and flatten out as they reach the curve.

| I plastered 2 cool ceilings about 1986 in

Midland, Virginia. I used 3.4 diamond mesh lath and a sand plaster basecoat. I call these ceilings "boat ceilings' because they look like an upside down boat. They are sort of a rectangular dome. The arrises (inside corners) start out as a sharp corner and flatten out as they reach the curve. |

|

|

|

| I took these pictures in 1991 with a film camera, before

the digital age. The project is a light troffer shaped like

the letter "D", looking from the top. The troffer is in the front entrance of of hospital we were plastering. We cut a hole in the lath to run our pipe to the deck above. A larger pipe is sleeved over and pivots for our swing arm. |

Swing arm pipes are welded together. A bracket supports the mold templates. The union steam fitters on the job provided the welding equipment and pipes. |

|

|

| Bracket supports the template to run the bull nose detail.

We filled in with moulding plaster and lime, and after several passes, our bullnose was complete. We used the same bracket to run the cove in the back. |

Bracket was designed to slide back. This allowed us to

pivot the swing arm back without scraping the finish work. We just had to retract the template to swing it back for every pass. |

| More old pictures | |

|

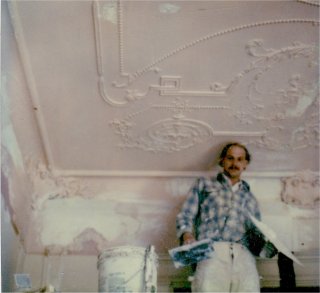

This is a picture of me about 1977, restoring a beautiful old ornamental plaster ceiling in Richmond, VA that was butchered in a remodeling project. |

| More old blurry pictures | Old CIA headquarters on F St. in Washington, DC |

|

|

| This pose shows the mold template we used to run the top moulding. | The bottom and moulding were run at the same time. I scanned these old pictures and edited them with Paint Shop Pro. You can still barely see the moldings. |

|

|

| The egg and dart and dentil were cast with latex and stuck up in sections. | Barry saws the cast pieces to length before we stuck them up. |