|

|

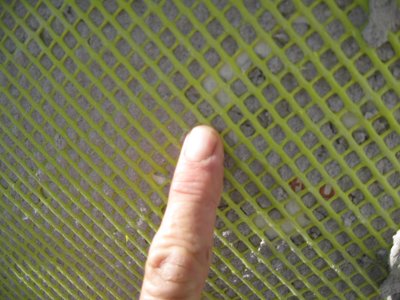

We use metal lath for our jobs. I'm glad I never

got sucked into buying this plastic lath. After a few seasons, it

deteriorated to the point that it could be ripped off the wall easily,

like paper.

|

Lath lies flat on the wall, not allowing for

mortar

to squish behind it. As a result, very little support

is provided.

|

|

|

Another monument to mediocrity is this pile of

plastic lath on the ground. The stucco wrap

is also deteriorated and has the same resistance

as newspaper.

|

Stucco wrap waiting to be torn off.

|

|

|

After a layer of tar paper, metal lath, the brown coat is on.

I lost my camera so I'm am missing pictures for what happened in

between.

|

Slate roof is protected with Styrofoam. These

roofs break easily, and are expensive to repair.

Styrofoam is the ticket for cushioning the weight

of the scaffold boards.

|

|

|

Metal roof is protected with a layer of plastic and

Styrofoam.

|

Finish coat is white Portland cement and white sand. The

color is a custom color from Expo stucco in San Diego.

|

|

|

A view of the back wall.

|

Kick out flashing is a piece of sheet metal we

put on behind the roof flange. This way, water is diverted into the

gutter and doesn't run down

behind the gutter into the wall.

|