|

|

| Mouldings are straight. Inside is tooled with a miter rod. |

Mold template, also called a running mold is used to run the molding in place.

|

|

|

| Badly water damaged moulding had been patched numerous times. |

Section is removed to make a template.

|

|

|

| We got the section off in two pieces. |

I got an aluminum sign to make templates out of from the

scrap metal yard on Kenilworth Avenue. Rebuilding DC seemed appropriate

for this project.

|

|

|

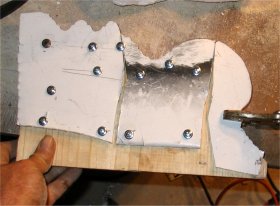

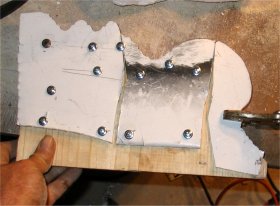

| Metal is filed and fitted by filing a little at a time. |

I made the metal in 3 pieces and screwed it to a wood back up. It took me 12 hours to make this template.

|

|

|

| Mouldings and sagging area of ceiling torn out. |

Ceiling is filled with metal lath and moulding plaster and lime. Ceiling is straightened with a rod. The ceiling must be dead straight at the moulding for all this to work.

|

|

|

| Template is screwed to a bottom piece, or a sled, and a brace is attached. |

After putting up metal lath, moulding is filled a little at a time and run with the template.

Straight lumber is screwed to the wall for the sled to ride on.

|

|

|

| A close up showing the moulding detail. |

The gap between the mouldings is filled and tooled. Here, a special tool is used to fill the round members.

|

The inside corners, or miters, are tooled in with rods called mitering rods. The inside corners, or miters, are tooled in with rods called mitering rods. |

|

The inside corners, or miters, are tooled in with rods called mitering rods.

The inside corners, or miters, are tooled in with rods called mitering rods.