in 3 days after we set up the scaffold.

The best tool we found to do this is a

flat garden spade. for more.

foam is easily scraped off.

for more

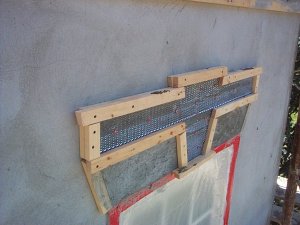

metal lath.

groover. These make a far better joint

than the pre-manufactured metal joints.

That is, a wood strip is set with a string line.

the strips with a white pine 1 x 4.

An old plasterer once told me you can

do some nice work with white pine.

with furring strips.

the jack arch and the second third of

the keystone. This is formed after the

first projection is filled with lath and

mortar and allowed to set up overnight.

The third projection will be the keystone.

filled with lath and mortar. This is the hard

way, but far better than gluing flimsy foam

to the wall.