|

|

Paint is chipped off brick, concrete and

other

surfaces.

Loose areas on sand brick and other

materials removed. |

Plenty of flex-con

is used here in the mortar to assure a good bond. First a

scratch coat

is applied and allowed to set two days. |

|

|

| Brown coat applied. Look any straighter? |

Wall is trued by propping rod against back

side

and filling

in. |

|

|

| PVC weeps are cut through wall and patched in. These are

critical to

the life of the wall by allowing water to drain out. Weeps

are angled

down

and protrude past the finished wall surface about an inch. A

weep flush

with the finished wall would allow water to run behind the

stucco,

causing

failure of the stucco over time. |

Tom put additional weeps in the wall using

these

copper tubes. |

|

|

| Copper pipe is cut off and flared with a flaring tool. |

We finished the wall just four days before this

huge snow storm hit. |

|

|

| Chimney was never finished back in the 1930's. Someone got

lazy or

just ran out of flues. |

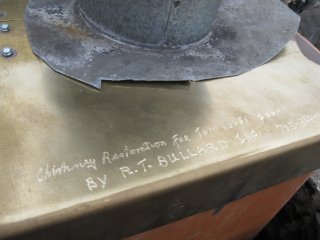

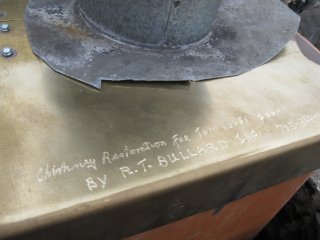

New flue is capped with this brass plaque Tom

made. Inscription reads "chimney restoration for Tom 2009 by

R T

Bullard,

Inc. 703-845-1565". Maybe someone will go up here one day

and read this. |

|

|

| Safe level scaffold is made using these plaster jacks and

nailing the

boards together around the chimney. Roof is covered with tar

paper and

drop

cloths. Bricks on chimney are covered with plastic. |

New flues put on, chimney filled with mortar and cap

formed. |

|

I embedded my usual coins in the chimney as a time

capsule.

Finish is REAL Portland cement

and REAL sand. Greenish color is from EXPO stucco in San

Diego. |

Chimney cap color matches the retaining wall.

This chimney should now last for centuries.

|

|