Jobs in progress

updated May 25, 2012

Over

13 years of jobs in progress, update #123!

Jobs in progress

contains some 400+ pages. Here, you will find a wealth of informaton on the

world's oldest building trade, plaster,

both interior plaster, and exterior cement plaster, also known as

stucco. Please check it out.

A table of contents is forthcoming, like I did on the Stucco News.

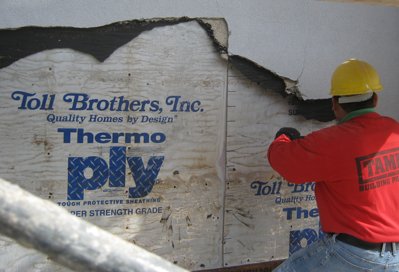

Toll Brothers garbage

replaced in Vienna, Virginia

|

Somebody nailed metal lath on cardboard.

Therma ply is silver cardboard, and isn't meant

to carry the weight of mortar. This is the reason

these walls were buckling and falling off.

This was one of the houses that

Toll Brothers

replaced the EIFS with one-coat synthetic

sono wall.

Over 140 houses in northern

Virginia were done

by a unlicensed contractor from Chicago.

You have to be mighty stupid to

nail metal lath to

therma ply.

Of course, we nailed the new lath to the studs.

|

|

|

Finished Product:

Self-furring metal lath, nailed to the studs this time, an

honest 3/4" cement basecoat with a real Cement and sand

finish coat.

The wall is later painted

to match the toxic synthetic

finish on the rest of the

house.

Please click here or on the pictures for more.

|

The chimney,

also was loose and ready to pop off.

You could wiggle the stucco

with your hand. If you live

in a Toll Bros. house,

maybe you should wear a hard hat.

Note how the synthetic

finish bubbles up when it

traps water.

More details here

|

|

|

The walls here

are so loose you can wiggle them.

Toll Brothers replaced EIFS on over 140 houses in

northern Virginia about 2003 with this junk, metal lath, a

thin cement basecoat, and a synthetic finish.

Please click here or on the pictures for more.

|

Tell me this

chimney doesn't leak. A couple shovelfuls of mortar may

have saved this chimney. This is fast and cheap for you.

More details here

|

Stucco

make over in Arlington, VA

|

|

|

BEFORE:

The old wall was a little

shabby looking.

The top was flat allowing

water to penetrate over

the years.

Please

click here or on the pictures to see how

we did it. |

|

AFTER:

I cast a medallion to put

on the finished wall.

The top was rounded off for

good water runoff, so maybe it will last longer this time.

Please

click here or on the pictures to see how

we did it.

|

|

|

|

BEFORE:

Front entrance wall had

seen better days.

Please

click here or on the pictures to see how

we did it. |

|

AFTER:

The front wall was extended

up 2 courses of block and re-stuccoed. How do you like my round peek through ?

Please

click here or on the pictures to see how

we did it. |

|

|

|

BEFORE:

Deteriorated areas were

chopped out and filled in.

Please

click here or on the pictures to see how

we did it. |

|

AFTER:

The wall was extended up 3

courses of block for privacy and re-stuccoed to look like

new.

Please

click here or on the pictures to see how

we did it. |

Stucco replaced in

Arlington, Virginia

ABOVE:

^

Old stucco stripped off to the old wood lath.

LEFT:

----------->

Badly deteriorated chimney repaired.

Please

click here or on the pictures for more.

|

|

Stucco chimney

replaced in Washington, DC

The top of this chimney was

left wide open when

the stucco was done about

30 years ago, leading to rot.

The whole thing was torn

down and rebuilt.

|

. .

|