Cool stucco fire pit and seat in

Arlington, Virginia

The fire pit is heated with a gas log and is filled with gravel

Curved seat starts out as blocks.

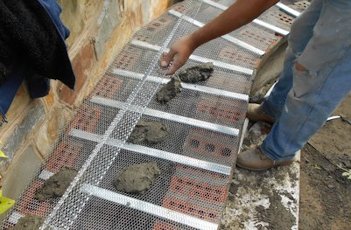

The seat itself is made using inch and a

half channel iron and metal lath. Here a piece of

corner rite, a strip of lath bent at an angle, is

used to reinforce the seat and the backrest.

Bricks are used for the fire pit to

allow a tighter radius.

No, we aren't bricklayers. We only lay bricks

when they get stuccoed over and don't matter

much what they look like.

Stucco addition on a Spanish style house

in Chevy Chase.

This Spanish style house has a Spanish

tile roof and a Spanish texture. You can't get much

more Spanish than this without going to Spain.

Stucco arches and

decorative cast columns accent the Spanish

style.

Original Spanish texture. Window surrounds are painted on.

Historic aggregated stucco

in Afton, Virginia

A view of the old house shows different

colored rocks and crushed green glass embedded in

the stucco. The old glass was made from wine

bottles broken up and screened to size.

Another satisfied customer poses with pride.

I matched the rock color fairly close and

screened the rocks to size. I used stained glass

instead of wine bottles. I got a reflective green glass

from Jed at Washington Art Glass.

Retaining walls done by the competition re-done

in Washington, DC

Serpent like retaining walls are

re-stuccoed.

You can see my heater in the background.

Eight year old synthetic stucco finish is

badly deteriorated. The whole house can be peeled off with

your fingernail. This material, when applied over a cement

basecoatlasts less than 8 years.

Garage and

retaining walls stuccoed to match

in Washington, DC

A close up of the dash on texture

on this

Wardman house. Wardman built a lot of

houses and over 20 apartment buildings in Washington in

the 1920's and 30's.

Dash on stucco texture on this concrete retaining wall.

A close up of the dash on texture

on this Wardman house in Washington DC

Basement on this old house

livened up with white pebble dash stucco in Chevy Chase

White pebble dash stucco in Chevy

Chase

We're patching a lot of plaster these days seeing how it is cold outside.